DESCRIPTION AND GENERALITIES

The CPK centrifugal pumps are constructed following the process and in accordance with DIN 24.256 for chemical industry.

All pump sizes of this type are graduated in relation to each other. This fact can give the best efficency and the right NPSH value for each case.

APPLICATION AND SERVICES

The CPK series are used for chemical food, pharmaceutical and textil industries, as well as for heating plants and high temperatures plants, and for many other general uses.

CPK pumps are supplied for the following futy conditions: Q up to 1.300 m3/h, total heads up to 150 m.c.l. at temperatures of 300°C, and final pressures of 25 kg / cm2.

CONSTRUCTION

Normalized pump in accordance with DIN 24.256, and for vertical construction.

CASING

Volute casing in spiral open towards the discharge side, foot support at the botton with end suction nozzle, and with double spiral from the 315 size.

IMPELLER

Closed radial impeller, with hydraulic compensation by edge blades.

SHAFT AND BEARINGS

Five sizes of bearing support cover the whole pump range, bearings lubricated by oil. All bearings supports are supplied with and oil level controller.

In the heavy duty bearing execution, cylindrical roller bearing goes in pump size and the angular contact ball bearing goes in motor side.

SHAFT SEAL

Packing stuffing box connection for seal liquid, or cleaning liquid, with cooled/heating stuffing box in all pumps.

Mechanical seals of various manufacturers can be fitted.

EXECUTIONS

- Execution "R" Reinforced bearing support

- Execution "f" Special flanges

- Execution "m" Mechanical seal

- Execution "H" Heated (in case of pumping hot liquids

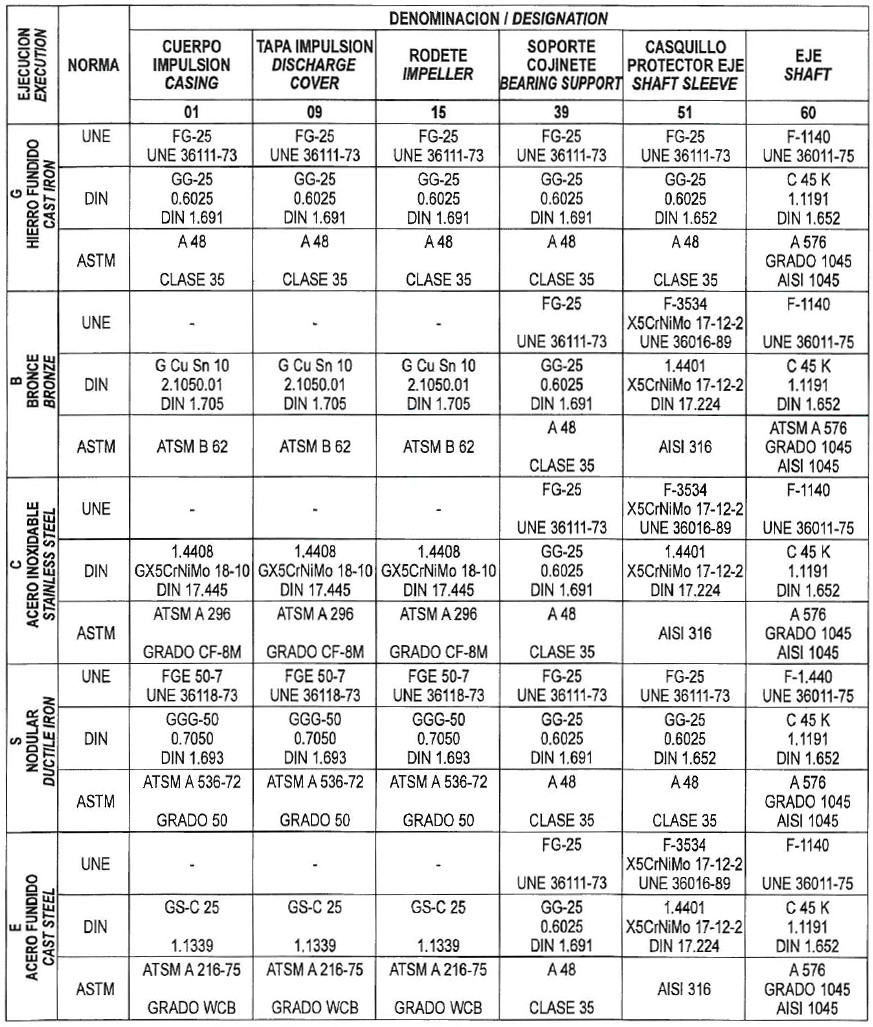

MATERIALS

The pump is supplied in five standard material executions:

- G (Cast iron)

- B (Bronze)

- S (Ductile iron)

- C (Stainless steel)

- E (Cast Steel)

Other materials combinations can be selected

depending on the fluid characteristics

to be pumped.

| |  Components designation

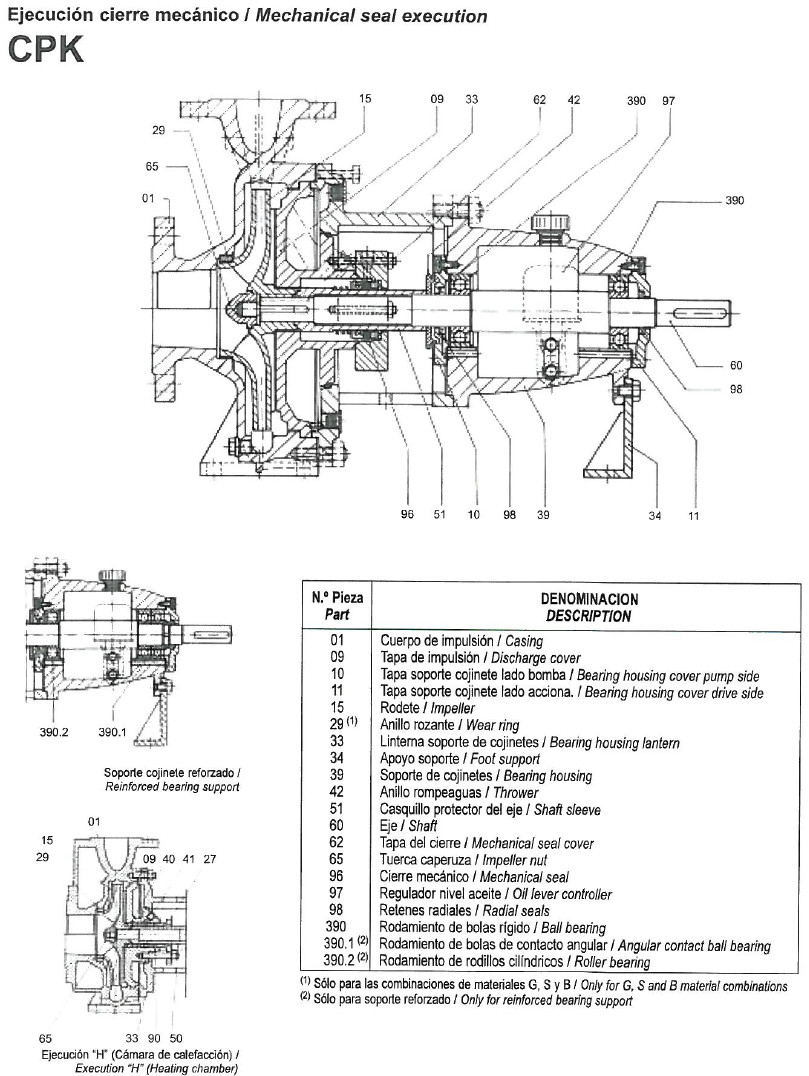

Sectional drawing & components list

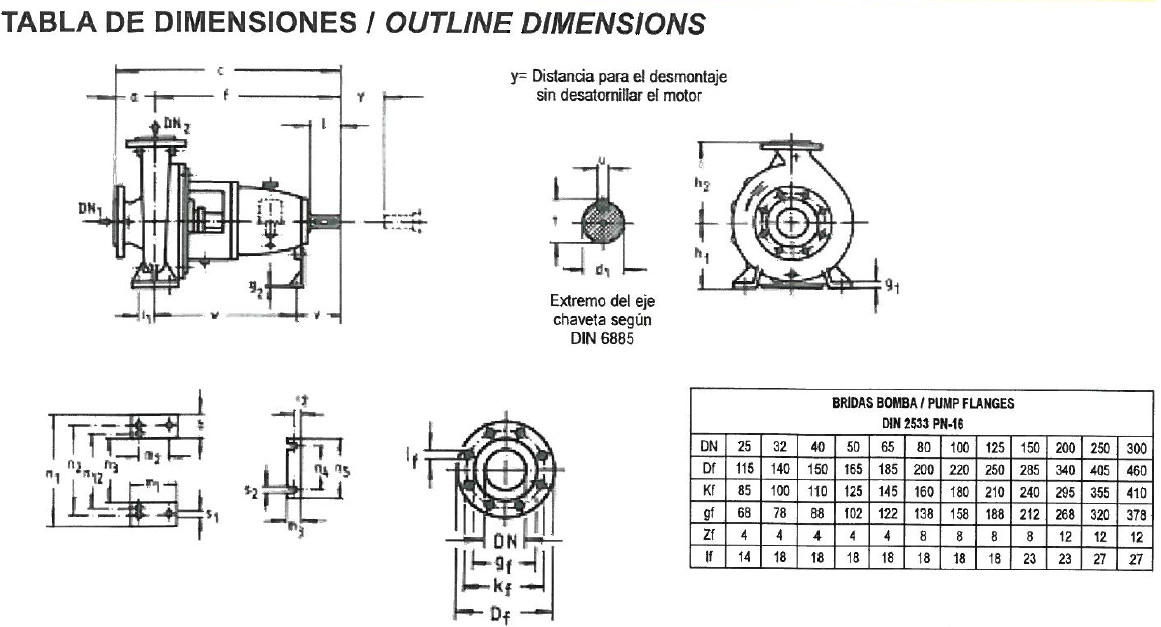

CPK series outline dimensions

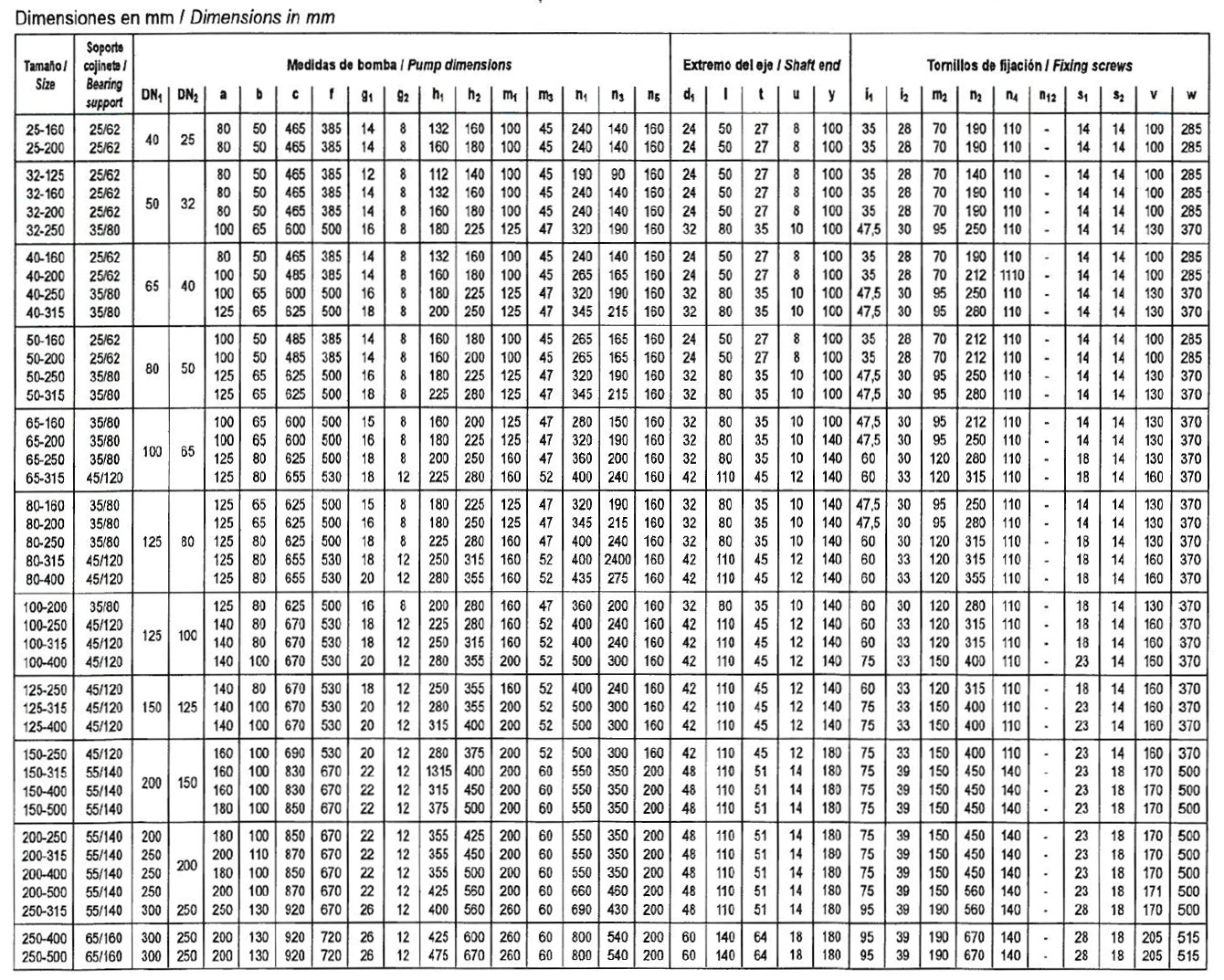

CPK series dimensions in mm |